The machine with fully enclosed grinding area,

increased power efficiency and digital control concept.

Characteristics

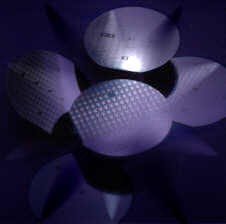

The MPS R400 DS line of machines have been designed to take advantage of

state-of-the-art grinding technologies and ergonomics. The fully

encapsulated grinding area offers optimum environmental conditions for

the operator and reduces risks of contamination. This concept has been

developed and refined for maximum precision when grinding metal, silicon

and other semiconductor materials in small batch production, research

and development.

Application

The major application is the grinding of silicon and GaAs

in the 50mm up to 150 mm range.

Features

Fully enclosed grinding area

Diamond grinding wheels

PLC- Control

Measuring Unit

Minimal TTV’s

Automatic programs

Vacuum chucks

Consistent grinding results

Special Option

MPS R400 DS + TWIN-SPINDLE

The TWIN-SPINDLE concept shows several opportunities:

Two grinding wheels on one spindle

Roughing and finishing in one setting

High stock removal at fines finishes

Unbeatable work piece geometry

No wheel change between roughing and fine finishing

No secondary or rechecking of work piece for fine finishing

Shortest change-over times

JSP Technology, Inc.