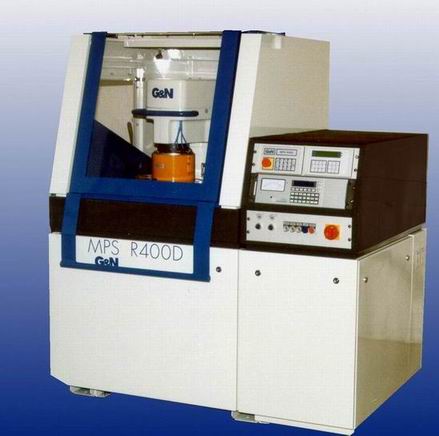

Precision Surface Grinding Machine MPS R400 D

Application areas

Roughing and finishing of hardened steel, metals, hard alloys, ferrites

and other material (glass, ceramic). The fully automatic down feed

system enables optimal use in serial production at highest precision.

Accessories

Magnetic chucks

Special chucking device

Paper filter system

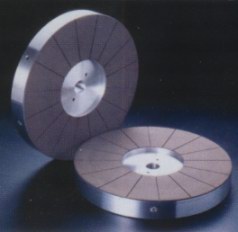

CBN wheels

Diamond wheels

Properties

Fully enclosed grinding area for optimal working comfort and security

- no contamination.

Automatic down feed system by four phase stepping motor, infinitely

variable down feed speed.

Gauging unit (optimal device) enables compensation of wheel wear and

thermal effects – minimal thickness variations when grinding metal with

vitrified wheels.

Special Option

MPS R400 D + TWIN-SPINDLE

The TWIN-SPINDLE concept shows several opportunities:

Two grinding wheels on one spindle

Roughing and finishing in one setting

High stock removal at fines finishes

Unbeatable work piece geometry

No wheel change between roughing and fine finishing

No secondary or rechecking of work piece for fine finishing

Shortest change-over times

Models

JSP Technology, Inc.